-

Internal siab hydroforming ntau lawm kab

Internal high-pressure forming, tseem hu ua hydroforming los yog hydraulic forming, yog cov khoom tsim cov txheej txheem uas siv cov kua ua qhov nruab nrab thiab ua tiav lub hom phiaj ntawm kev tsim cov hollow qhov chaw los ntawm kev tswj lub siab thiab cov khoom ntws. Hydro Forming yog ib hom kev siv tshuab hydraulic. Nws yog cov txheej txheem uas lub raj siv los ua billet, thiab lub raj xa hluav taws xob yog nias rau hauv pwm kab noj hniav los tsim cov khoom ua haujlwm uas yuav tsum tau ua los ntawm kev siv cov kua dej ultra-siab thiab axial pub. Rau qhov chaw nrog nkhaus axes, lub raj billet yuav tsum tau pre-bent rau hauv cov duab ntawm ib feem thiab ces pressurized. Raws li hom kev tsim qhov chaw, lub hauv siab siab sib sau yog muab faib ua peb pawg:

(1) txo cov raj hydroforming;

(2) raj hauv dabtsi yog khoov axis hydroforming;

(3) multi-pass raj high-pressure hydroforming. -

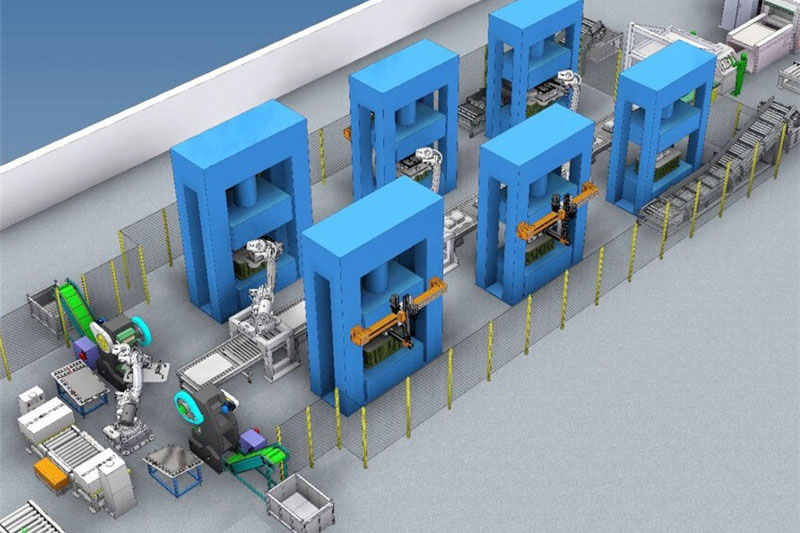

Fully Automated Sheet hlau Stamping Hydraulic Xovxwm Ntau Lawm Kab rau tsheb

Lub Siab Automated Automotive Sheet hlau Stamping Hydraulic Xovxwm Ntau lawm kab revolutionizes cov tsoos phau ntawv noj thiab unloading siab tshuab los ua ke kab los ntawm incorporating neeg hlau caj npab rau automated khoom tuav thiab nrhiav kom tau zog. Cov kab mob stroke tas mus li no ua rau muaj kev tsim khoom ntse hauv cov chaw ua haujlwm stamping nrog kev ua haujlwm tsis muaj neeg ua haujlwm thoob plaws hauv cov txheej txheem tsim khoom.

Cov kab ntau lawm yog cov kev daws teeb meem uas tsim los txhim kho cov txheej txheem tsim khoom ntawm cov khoom siv tsheb. Los ntawm kev hloov phau ntawv ua haujlwm nrog cov caj npab neeg hlau, cov kab ntau lawm no ua tiav kev pub noj thiab tshem tawm cov ntaub ntawv, thaum tseem suav nrog kev tshawb nrhiav qib siab. Nws ua haujlwm ntawm hom kev tsim tawm tsis tu ncua, hloov cov khoom lag luam stamping rau hauv cov chaw tsim khoom ntse.

-

Tuag Tryout Hydraulic Xovxwm rau Automotive Part Tooling

Advanced Die Tryout Hydraulic Xovxwm, tsim los ntawm JIANGDONG MACHINERY yog ib qho kev hloov kho tshiab ntawm ib qho kev ua ntawv hlau stamping hydraulic xovxwm. Tsim tshwj xeeb rau tsheb qhov pwm debugging, nws nta cov kev kho mob stroke muaj peev xwm. Nrog rau qhov zoo-tsim qhov tseeb txog li 0.05mm rau ib qho mob stroke thiab ntau hom kev hloov kho nrog rau kev hloov kho plaub-point, hydraulic servo hloov, thiab lub zog-tsawg downward zog, hydraulic xovxwm no muab tshwj xeeb precision thiab yooj rau pwm kuaj thiab validation.

Advanced Die Tryout Hydraulic Xovxwm yog ib qho kev daws teeb meem uas tsim los ua kom tau raws li qhov tshwj xeeb ntawm cov pwm debugging rau tsheb qhov chaw. Ua raws li lub hauv paus ntawm ib daim ntawv ua haujlwm ib zaug hlau stamping hydraulic xovxwm, lub tshuab tshiab no qhia txog kev hloov kho mob stroke siab los xyuas kom meej kev sim thiab kev siv tau ntawm cov tsheb pwm. Nrog peb hom kev hloov kho sib txawv muaj, cov neeg ua haujlwm muaj qhov yooj yim xaiv txoj kev kho kom zoo rau lawv cov kev xav tau tshwj xeeb.

-

Tuag Spotting Hydraulic Xovxwm rau Precision Pwm Kho

Die Spotting Hydraulic Xovxwm yog lub tshuab tshwj xeeb tsim los rau kev ua pwm pwm thiab hloov kho. Nws yog qhov tshwj xeeb tshaj yog tsim rau kev tsim thiab kho qhov nruab nrab mus rau qhov loj-scale stamping pwm, muab pwm kev sib raug zoo, raug debugging, thiab muaj peev xwm ua tiav. Cov xovxwm hydraulic no tuaj nyob rau hauv ob hom qauv: nrog los yog tsis muaj pwm flipping ntaus ntawv, nyob ntawm seb hom pwm thiab cov txheej txheem pom. Nrog rau nws cov kev tswj xyuas mob stroke siab precision thiab adjustable stroke muaj peev xwm, hydraulic xovxwm muaj peb qhov sib txawv zoo-tuning xaiv: mechanical plaub-point adjustment, hydraulic servo hloov, thiab siab-tsawg downward zog.

Lub Die Spotting Hydraulic Xovxwm yog ib qho kev siv thev naus laus zis tshwj xeeb uas tsim los rau kev ua pwm thiab kev hloov kho hauv kev lag luam xws li tsheb, aerospace, thiab kev tsim khoom. Nws cov kev tswj xyuas mob stroke thiab yooj yim ua rau nws yog ib qho khoom siv tsis tseem ceeb rau pwm debugging, sib dhos, thiab ua kom raug.

-

Nruab nrab thiab tuab phaj stamping thiab kos duab hydraulic xovxwm ntau lawm kab

Peb cov txheej txheem nruab nrab-Thick Plate Deep Drawing Ntau Lawm Kab muaj tsib hydraulic presses, cov menyuam conveyors, thiab siv conveyors. Nrog nws cov pwm hloov pauv sai, cov kab ntau lawm no ua kom nrawm thiab ua haujlwm zoo pwm swapping. Nws muaj peev xwm ua tiav 5-kauj ruam tsim thiab hloov cov khoom ua haujlwm, txo kev siv zog ua haujlwm, thiab ua kom yooj yim rau kev tsim cov khoom siv hauv tsev. Tag nrho cov kab ntau lawm yog tag nrho automated los ntawm kev sib koom ua ke ntawm PLC thiab kev tswj hwm hauv nruab nrab, ua kom muaj txiaj ntsig zoo.

Cov Kab Ntau Lawm yog ib qho kev daws teeb meem uas tsim los rau kev tsim cov khoom sib sib zog nqus los ntawm cov phaj tuab tuab. Nws muab lub zog thiab qhov tseeb ntawm hydraulic presses nrog kev yooj yim ntawm kev siv cov khoom siv tes ua haujlwm, uas ua rau muaj txiaj ntsig zoo dua qub thiab txo qis kev ua haujlwm.

-

Single-action Sheet hlau Stamping Hydraulic Xovxwm

Peb Ib Leeg-Action Sheet Hlau Stamping Hydraulic Xovxwm yog muaj nyob rau hauv ob qho tib si plaub-kem thiab ncej. Nruab nrog ib tug downward stretching hydraulic cushion, no xovxwm enables ntau yam xws li hlau ntawv stretching, txiav (nrog buffering ntaus ntawv), dabtsi yog khoov, thiab flanging. Cov cuab yeej muaj kev ywj pheej hydraulic thiab hluav taws xob, tso cai rau kev hloov kho thiab ob txoj haujlwm ua haujlwm: lub voj voog tsis tu ncua (semi-automatic) thiab kev hloov kho ntawm phau ntawv. Cov kev ua haujlwm xovxwm muaj xws li hydraulic cushion lub tog raj kheej tsis ua haujlwm, ncab, thiab rov qab ncab, nrog kev xaiv tsis siv neeg ntawm qhov siab thiab mob stroke rau txhua hom. Siv dav hauv kev lag luam automotive rau stamping ntawm nyias daim hlau cov khoom, nws siv stretching pwm, xuas nrig ntaus tuag, thiab kab noj hniav pwm rau cov txheej txheem xws li stretching, xuas nrig ntaus, khoov, trimming, thiab fine finishing. Nws cov ntawv thov kuj tseem txuas ntxiv mus rau aerospace, tsheb thauj mus los, kev ua liaj ua teb, khoom siv hauv tsev, thiab ntau lwm yam.

-

Tsheb Sab Hauv Hydraulic Xovxwm Thiab Kab Ntau Lawm

Lub Tsheb Sab Hauv Xovxwm thiab Cov Kab Ntau Lawm tsim los ntawm JIANGDONG MACHINERY feem ntau yog siv rau cov txheej txheem txias thiab kub compression molding txheej txheem ntawm tsheb sab hauv xws li dashboards, ntaub pua plag, qab nthab, thiab rooj zaum. Nws tuaj yeem nruab nrog cov tshuab cua sov xws li roj thermal lossis chav ua haujlwm raws li cov txheej txheem yuav tsum tau ua, nrog rau kev pub mis tsis siv neeg thiab tshem tawm cov khoom siv, cov khoom siv cua sov qhov cub, thiab cov khoom siv nqus tsev los tsim cov kab ntau lawm.

-

Tsis Siv Neeg High-Speed Fine-Blanking hydraulic xovxwm kab rau hlau Cheebtsam

Tsis Siv Neeg High-Speed Fine-Blanking hydraulic xovxwm kab yog tsim los rau precision blanking txheej txheem ntawm hlau Cheebtsam, tshwj xeeb tshaj yog catering rau zus tau tej cov automotive lub rooj adjuster qhov chaw xws li racks, iav phaj, lub kaum sab xis adjusters, raws li zoo raws li brake Cheebtsam xws li ratchets, pawls, adjuster daim hlau, rub caj npab, laub rods, lub plab daim hlau. Tsis tas li ntawd, nws tseem siv tau rau kev tsim cov khoom siv hauv lub rooj zaum, xws li buckle tongues, puab iav rings, thiab pawls. Cov kab ntau lawm no muaj cov khoom siv high-precision nplua-blanking hydraulic xovxwm, peb-hauv-ib qho khoom noj tsis siv neeg, thiab lub tshuab tsis siv neeg tshem tawm. Nws muaj kev pub mis tsis siv neeg, tsis siv neeg blanking, tsis siv neeg kev thauj mus los, thiab tsis siv neeg khib nyiab txiav ua haujlwm. Cov kab ntau lawm tuaj yeem ua tiav lub voj voog ntawm 35-50spm.web, txhawb phaj; Latch, puab nplhaib, ratchet, thiab lwm yam.

-

Tsheb Qhov Rooj Hemming Hydraulic Xovxwm

Lub Tsheb Qhov Rooj Hemming Hydraulic Xovxwm yog tsim tshwj xeeb rau cov txheej txheem hemming thiab blanking thiab trimming ua haujlwm ntawm sab laug thiab sab xis lub tsheb qhov rooj, lub hau npog, thiab lub cav npog. Nws yog txawm peem rau nrog ib tug ceev tuag hloov system, ntau yam movable workstations nyob rau hauv ntau yam ntaub ntawv, ib tug tsis siv neeg tuag clamping mechanism, thiab ib tug tuag paub system.

-

stainless hlau dej dab dej ntau lawm kab

Lub stainless hlau dej dab dej ntau lawm kab yog ib tug automated manufacturing kab uas muaj xws li cov txheej txheem xws li steel coil unwinding, txiav, thiab stamping los tsim cov dab dej. Cov kab ntau lawm no siv cov neeg hlau los hloov cov neeg ua haujlwm hauv phau ntawv, tso cai rau kev ua tiav ntawm lub dab ntxuav muag.

Stainless hlau dej dab dej ntau lawm kab muaj ob qhov tseem ceeb: cov khoom siv thiab lub dab dej stamping unit. Ob qhov no yog txuas nrog lub logistics hloov chaw, uas pab txhawb kev thauj mus los ntawm cov khoom nruab nrab ntawm lawv. Cov khoom siv hauv tsev muaj xws li cov khoom siv xws li coil unwinders, film laminators, flatteners, cutters, thiab stackers. Lub logistics hloov chaw muaj xws li cov tsheb thauj mus los, cov khoom siv stacking kab, thiab khoob pallet cia kab. Lub tshuab stamping muaj plaub txheej txheem: lub kaum sab xis txiav, thawj stretching, theem nrab stretching, ntug trimming, uas koom nrog kev siv hydraulic presses thiab neeg hlau automation.

Lub peev xwm ntau lawm ntawm cov kab no yog 2 daim ib feeb, nrog rau txhua xyoo tso zis ntawm kwv yees li 230,000 daim.

-

Kev kub ceev kub Stamping Ntau Lawm Kab rau ultral high-Strength Steel (Aluminium)

Kev kub ceev kub Stamping Ntau Lawm Kab rau ultral high-Strength Steel (Aluminium) yog lub xeev-of-the-art manufacturing tov rau tsim complex-shaped automotive lub cev qhov chaw siv cov txheej txheem kub stamping. Nrog cov yam ntxwv xws li cov khoom noj ceev ceev, kub stamping hydraulic xovxwm, cov pwm dej txias, cov khoom siv tsis siv neeg retrieval, thiab cov kev xaiv ua tom ntej xws li kev txhaj tshuaj blasting, laser txiav, los yog tsis siv neeg trimming thiab blanking system, cov kab ntau lawm no muaj kev ua haujlwm tshwj xeeb thiab kev ua haujlwm zoo.

-

Ultra High Strength Steel (Aluminium) Tsis Siv Neeg Txias Txiav / blanking Ntau Lawm Kab

Ultra High Strength Steel (Aluminium) Tsis Siv Neeg Txias Txiav Ntau Lawm Kab yog lub xeev-of-the-art automated system tsim los rau tom qab ua tiav ntawm high-strength steel los yog txhuas tom qab kub stamping. Nws ua haujlwm zoo hloov pauv rau cov khoom siv laser tej tsoos. Cov kab ntau lawm no muaj ob lub tshuab hydraulic nrog cov cuab yeej txiav, peb lub caj npab robotic, lub tshuab tsis siv neeg thauj khoom thiab tshem tawm, thiab kev sib kis tau zoo. Nrog nws cov peev xwm automation, cov kab ntau lawm no pab txhawb kev ua haujlwm tas mus li thiab ua haujlwm siab.

Ultra High Strength Steel (Aluminium) Automatic Cold Cutting Production Line yog tsim tshwj xeeb rau kev ua tiav tom qab ua tiav ntawm cov khoom muaj zog steel lossis txhuas cov ntaub ntawv tom qab kub stamping txheej txheem. Nws muab cov kev daws teeb meem txhim khu kev qha los hloov cumbersome thiab siv sij hawm siv cov txheej txheem laser txiav. Cov kab ntau lawm no ua ke nrog cov thev naus laus zis siab, cov cuab yeej precision, thiab automation kom ua tiav seamless thiab ua haujlwm tau zoo.