Cov Kab Ntau Lawm Kub Kub Ceev rau Cov Hlau Muaj Zog Ultral (Aluminium)

Cov yam ntxwv tseem ceeb

Cov Kab Ntau Lawm no yog tsim los ua kom cov txheej txheem tsim khoom ntawm cov khoom siv hauv tsheb zoo dua los ntawm kev siv cov thev naus laus zis kub stamping. Cov txheej txheem no, hu ua kub stamping hauv Asia thiab nias hardening hauv Tebchaws Europe, cuam tshuam nrog kev ua kom cov khoom dawb paug sov rau qhov kub tshwj xeeb thiab tom qab ntawd nias nws hauv cov pwm sib xws siv cov thev naus laus zis hydraulic nias thaum tswj hwm qhov siab kom ua tiav cov duab xav tau thiab dhau los ua theem hloov pauv ntawm cov khoom siv hlau. Cov txheej txheem kub stamping tuaj yeem faib ua cov txheej txheem kub stamping ncaj qha thiab tsis ncaj qha.

Cov txiaj ntsig

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm cov khoom siv kub-stamped yog lawv qhov zoo heev formability, uas tso cai rau kev tsim cov geometries nyuaj nrog lub zog tensile tshwj xeeb. Lub zog siab ntawm cov khoom siv kub-stamped ua rau siv cov ntawv hlau nyias dua, txo qhov hnyav ntawm cov khoom thaum tswj kev ruaj khov ntawm cov qauv thiab kev ua haujlwm sib tsoo. Lwm cov txiaj ntsig suav nrog:

Kev Ua Haujlwm Txo Kev Sib Koom Tes:Kev siv tshuab kub stamping txo qhov xav tau kev vuam lossis kev sib txuas ua haujlwm, ua rau muaj kev ua haujlwm zoo dua thiab txhim kho kev ua haujlwm ntawm cov khoom.

Txo Qhov Springback thiab Warpage Kom Tsawg:Cov txheej txheem kub stamping txo qis qhov tsis zoo uas tsis xav tau, xws li qhov chaw springback thiab warpage, kom ntseeg tau tias qhov tseeb ntawm qhov ntev thiab txo qhov xav tau kev ua haujlwm ntxiv.

Tsawg dua qhov tsis zoo ntawm qhov chaw:Cov khoom siv kub-stamped muaj tsawg dua qhov tsis zoo, xws li tawg thiab tawg, piv rau cov txheej txheem tsim txias, ua rau cov khoom zoo dua thiab txo cov khib nyiab.

Qis dua xovxwm Tonnage:Kev kub stamping txo qhov xav tau ntawm kev nias piv rau cov txheej txheem tsim txias, ua rau txuag tau nqi thiab ua kom muaj txiaj ntsig zoo dua.

Kev Kho Kom Zoo ntawm Cov Khoom Siv:Kev siv tshuab kub stamping tso cai rau kev hloov kho cov khoom siv raws li cov cheeb tsam tshwj xeeb ntawm qhov, ua kom zoo dua kev ua tau zoo thiab kev ua haujlwm.

Kev Txhim Kho Microstructural Zoo Dua:Kev kub stamping muaj peev xwm los txhim kho cov qauv me me ntawm cov khoom siv, ua rau muaj cov khoom siv kho tshuab zoo dua thiab ua kom cov khoom ruaj khov dua.

Cov Kauj Ruam Tsim Khoom Yooj Yim:Kev kub stamping tshem tawm lossis txo cov kauj ruam tsim khoom nruab nrab, ua rau cov txheej txheem tsim khoom yooj yim dua, txhim kho kev tsim khoom, thiab lub sijhawm ua khoom luv dua.

Cov Ntawv Thov Khoom

Cov Kab Ntau Lawm Uas Muaj Zog Siab (Aluminium) Kub Kub Ceev pom muaj kev siv dav hauv kev tsim cov khoom siv dawb ntawm lub cev tsheb. Qhov no suav nrog cov ncej sib dhos, cov bumpers, cov ntoo qhov rooj, thiab cov rooj sib dhos ntawm lub ru tsev siv rau hauv cov tsheb thauj neeg. Tsis tas li ntawd, kev siv cov hlau nplaum siab heev uas siv tau los ntawm kev kub kub tab tom raug tshawb nrhiav ntau ntxiv hauv kev lag luam xws li aerospace, kev tiv thaiv, thiab kev lag luam tshiab. Cov hlau nplaum no muab cov txiaj ntsig ntawm lub zog siab dua thiab txo qhov hnyav uas nyuaj rau ua tiav los ntawm lwm txoj hauv kev tsim.

Xaus lus, Txoj Kab Tsim Khoom Siv High-Strength Steel (Aluminium) High-Speed Hot Stamping ua kom muaj kev tsim khoom zoo thiab ua tau zoo ntawm cov khoom siv hauv lub cev tsheb uas muaj cov duab nyuaj. Nrog rau kev ua tau zoo dua, txo cov haujlwm sib koom ua ke, txo qhov tsis zoo, thiab cov khoom siv zoo dua, cov kab tsim khoom no muab ntau yam zoo. Nws cov ntawv thov nthuav dav mus rau kev tsim cov khoom siv hauv lub cev dawb rau cov tsheb thauj neeg thiab muab cov txiaj ntsig zoo hauv kev lag luam aerospace, kev tiv thaiv, thiab kev lag luam tshiab. Nqis peev rau hauv Txoj Kab Tsim Khoom Siv High-Strength Steel (Aluminium) High-Speed Hot Stamping kom ua tiav kev ua tau zoo tshaj plaws, kev tsim khoom, thiab kev tsim qauv sib dua hauv kev lag luam tsheb thiab kev lag luam koom tes.

Dab tsi yog kub stamping?

Kev kub stamping, tseem hu ua kev nias tawv hauv Tebchaws Europe thiab kev nias kub tsim hauv Asia, yog ib txoj kev tsim cov khoom siv uas qhov khoob raug cua sov rau qee qhov kub thiab tom qab ntawd stamped thiab quenched nyob rau hauv lub siab hauv lub pwm sib xws kom ua tiav cov duab xav tau thiab ua rau muaj kev hloov pauv theem hauv cov khoom siv hlau. Cov txheej txheem kub stamping suav nrog kev cua sov cov ntawv hlau boron (nrog lub zog pib ntawm 500-700 MPa) mus rau lub xeev austenitizing, sai sai hloov lawv mus rau lub pwm rau kev kub stamping, thiab quenching qhov hauv lub pwm ntawm tus nqi txias ntau dua 27 ° C / s, ua raws li lub sijhawm tuav nyob rau hauv lub siab, kom tau txais cov khoom siv hlau muaj zog heev nrog cov qauv martensitic sib xws.

Qhov zoo ntawm kev kub stamping

Txhim kho lub zog tensile kawg thiab lub peev xwm los tsim cov geometries nyuaj.

Txo qhov hnyav ntawm cov khoom los ntawm kev siv cov hlau nyias dua thaum tswj hwm kev ruaj khov ntawm cov qauv thiab kev sib tsoo.

Txo qhov xav tau kev sib txuas xws li kev vuam lossis kev khi.

Txo qhov feem uas poob rov qab thiab warping.

Tsawg dua qhov tsis zoo xws li tawg thiab tawg.

Qhov xav tau tonnage tsawg dua piv rau kev tsim khoom txias.

Muaj peev xwm hloov kho cov khoom siv raws li cov cheeb tsam tshwj xeeb.

Cov qauv microstructures txhim kho rau kev ua tau zoo dua.

Cov txheej txheem tsim khoom yooj yim dua nrog cov kauj ruam ua haujlwm tsawg dua kom tau txais cov khoom tiav.

Cov txiaj ntsig no pab txhawb rau qhov ua tau zoo, zoo, thiab kev ua tau zoo ntawm cov khoom siv kub stamped.

Xav paub ntxiv txog kev kub stamping

1. Kev Luam Kub thiab Kev Luam Txias

Kev kub stamping yog ib qho txheej txheem tsim uas ua tiav tom qab preheating lub hlau ntawv, thaum txias stamping txhais tau tias ncaj qha stamping ntawm hlau ntawv yam tsis muaj preheating.

Kev luam ntawv txias muaj qhov zoo dua li kev luam ntawv kub. Txawm li cas los xij, nws kuj muaj qee qhov tsis zoo. Vim yog qhov kev ntxhov siab ntau dua los ntawm cov txheej txheem luam ntawv txias piv rau kev luam ntawv kub, cov khoom lag luam luam ntawv txias yooj yim tawg thiab tawg. Yog li ntawd, cov khoom siv luam ntawv meej yog qhov xav tau rau kev luam ntawv txias.

Kev luam ntawv kub yog kev ua kom cov hlau kub ua ntej luam ntawv thiab tib lub sijhawm tua hluav taws hauv lub pwm. Qhov no ua rau cov hlau hloov pauv tag nrho mus rau hauv martensite, ua rau muaj zog siab txij li 1500 txog 2000 MPa. Yog li ntawd, cov khoom lag luam kub muaj zog dua piv rau cov khoom lag luam txias.

2. Cov Txheej Txheem Kub Stamping

Kev kub stamping, tseem hu ua "press hardening," cuam tshuam txog kev ua kom sov daim ntawv muaj zog siab nrog lub zog pib ntawm 500-600 MPa rau qhov kub ntawm 880 thiab 950 ° C. Tom qab ntawd daim ntawv kub raug stamped sai sai thiab quenched hauv lub pwm, ua tiav cov nqi txias ntawm 20-300 ° C / s. Kev hloov pauv ntawm austenite mus rau hauv martensite thaum lub sijhawm quenching ua rau lub zog ntawm cov khoom nce ntxiv, tso cai rau kev tsim cov khoom stamped nrog lub zog ntawm txog li 1500 MPa. Cov txheej txheem kub stamping tuaj yeem faib ua ob pawg: ncaj qha kub stamping thiab tsis ncaj qha kub stamping:

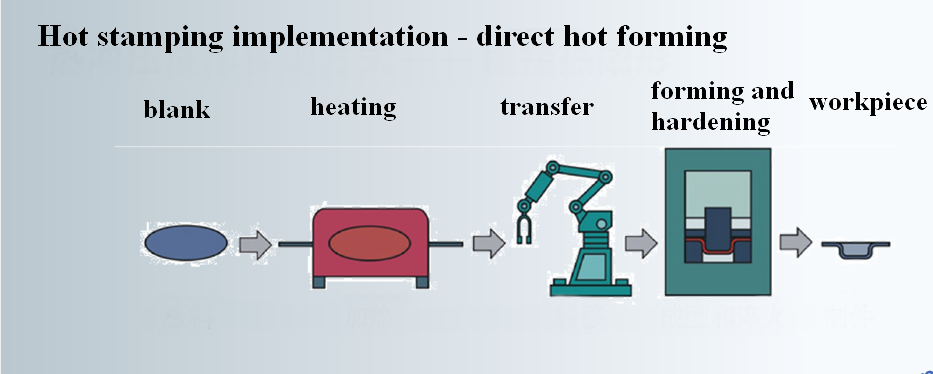

Hauv kev kub ncaj qha, cov khoom uas tau ua ntej lawm yuav raug pub ncaj qha rau hauv lub pwm kaw rau kev kub thiab quenching. Cov txheej txheem tom qab ntawd suav nrog kev txias, kev txiav ntug thiab kev xuas qhov (lossis txiav laser), thiab kev ntxuav qhov chaw.

Feature1: hom kev ua haujlwm kub stamping - ncaj qha kub stamping

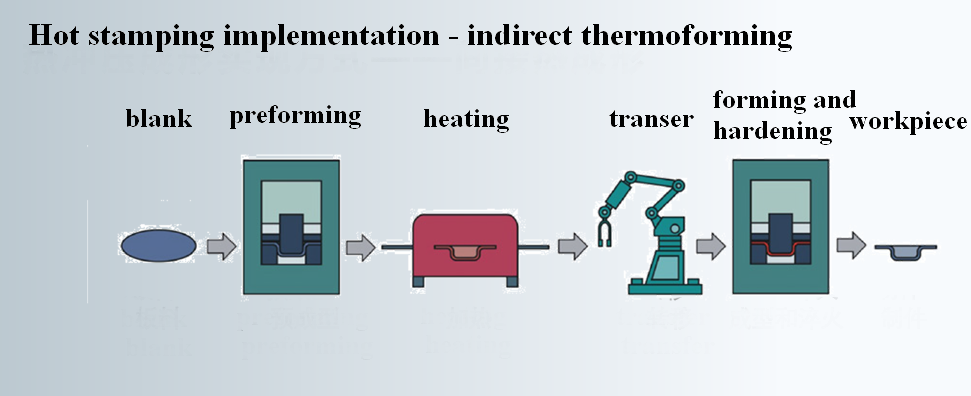

Hauv cov txheej txheem stamping kub tsis ncaj qha, cov kauj ruam ua ntej tsim cov duab txias yog ua ua ntej nkag mus rau theem ntawm kev cua sov, stamping kub, txiav ntug, xuas qhov, thiab ntxuav qhov chaw.

Qhov txawv tseem ceeb ntawm kev siv tshuab kub tsis ncaj qha thiab cov txheej txheem siv tshuab kub ncaj qha yog nyob rau hauv kev suav nrog cov kauj ruam ua ntej tsim cov duab txias ua ntej cua sov hauv txoj kev tsis ncaj qha. Hauv kev siv tshuab kub ncaj qha, cov hlau ntawv raug pub ncaj qha rau hauv lub cub tawg cua sov, thaum nyob rau hauv kev siv tshuab kub tsis ncaj qha, cov khoom ua ntej tsim cov duab txias raug xa mus rau hauv lub cub tawg cua sov.

Cov txheej txheem ntawm kev kub stamping tsis ncaj qha feem ntau muaj cov kauj ruam hauv qab no:

Kev tsim ua ntej txias--Kev cua sov--Kev kub stamping--Kev txiav ntug thiab xuas qhov--Kev ntxuav qhov chaw

Feature2: hom kev ua haujlwm kub stamping - indirect hot stamping

3. Cov khoom siv tseem ceeb rau kev kub stamping suav nrog lub cub tawg cua sov, lub tshuab ua kom kub, thiab cov pwm kub stamping

Cua Sov Rauv:

Lub cub tawg cua sov muaj peev xwm tswj tau qhov kub thiab txias. Nws muaj peev xwm ua kom cov phaj muaj zog siab mus rau qhov kub rov ua dua hauv lub sijhawm teev tseg, ua tiav lub xeev austenitic. Nws yuav tsum tau hloov kho rau cov kev xav tau ntau lawm tsis siv neeg. Vim tias cov hlau billet uas tau cua sov tsuas yog siv tau los ntawm cov neeg hlau lossis cov caj npab tshuab, lub cub tawg xav tau kev thauj khoom thiab tshem tawm tsis siv neeg nrog qhov tseeb siab. Tsis tas li ntawd, thaum ua kom cov hlau tsis muaj txheej, nws yuav tsum muab kev tiv thaiv roj kom tiv thaiv kev oxidation ntawm qhov chaw thiab decarbonization ntawm cov hlau billet.

Kub Tsim Xovxwm:

Lub tshuab nias yog lub hauv paus ntawm cov thev naus laus zis kub stamping. Nws yuav tsum muaj peev xwm rau kev stamping thiab tuav sai, nrog rau yuav tsum tau nruab nrog lub kaw lus txias sai. Qhov nyuaj ntawm kev tsim cov tshuab nias kub ntau dua li cov tshuab nias txias ib txwm muaj. Tam sim no, tsuas yog ob peb lub tuam txhab txawv teb chaws tau paub txog kev tsim qauv thiab kev tsim khoom ntawm cov tshuab no, thiab lawv txhua tus nyob ntawm kev xa khoom tuaj, ua rau lawv kim heev.

Cov pwm kub stamping:

Cov pwm kub stamping ua ob qho tib si theem tsim thiab theem quenching. Hauv theem tsim, thaum lub billet raug pub rau hauv qhov pwm qhov, lub pwm ua tiav cov txheej txheem stamping sai sai kom ntseeg tau tias ua tiav ntawm qhov tsim ua ntej cov khoom siv dhau los ntawm theem martensitic hloov pauv. Tom qab ntawd, nws nkag mus rau theem quenching thiab txias, qhov twg cua sov los ntawm cov khoom ua haujlwm hauv lub pwm raug xa mus rau lub pwm tas li. Cov kav dej txias uas teeb tsa hauv lub pwm tam sim ntawd tshem tawm cua sov los ntawm cov dej txias ntws. Kev hloov pauv martensitic-austenitic pib thaum qhov kub ntawm lub workpiece poob rau 425 ° C. Kev hloov pauv ntawm martensite thiab austenite xaus thaum qhov kub ncav cuag 280 ° C, thiab lub workpiece raug tshem tawm ntawm 200 ° C. Lub luag haujlwm ntawm lub pwm tuav yog los tiv thaiv kev nthuav dav thermal tsis sib xws thiab kev cog lus thaum lub sijhawm quenching, uas tuaj yeem ua rau muaj kev hloov pauv tseem ceeb hauv cov duab thiab qhov loj me ntawm qhov, ua rau muaj kev puas tsuaj. Tsis tas li ntawd, nws txhim kho kev hloov pauv thermal ntawm lub workpiece thiab lub pwm, txhawb kev quenching sai thiab txias.

Hauv kev xaus lus, cov khoom siv tseem ceeb rau kev kub stamping suav nrog lub cub tawg cua sov kom ua tiav qhov kub xav tau, lub tshuab kub rau kev kub stamping sai thiab tuav nrog lub kaw lus txias sai, thiab cov pwm kub stamping uas ua ob qho tib si tsim thiab quenching theem kom ntseeg tau tias muaj qhov tsim khoom zoo thiab txias zoo.

Qhov ceev ntawm kev quenching txias tsis yog tsuas yog cuam tshuam rau lub sijhawm tsim khoom xwb, tab sis kuj cuam tshuam rau kev hloov pauv ntawm austenite thiab martensite. Qhov ceev txias txiav txim siab seb hom qauv crystalline yuav tsim li cas thiab muaj feem cuam tshuam rau qhov kawg hardening ntawm workpiece. Qhov kub txias tseem ceeb ntawm boron steel yog li 30 ℃ / s, thiab tsuas yog thaum qhov txias txias tshaj qhov kub txias tseem ceeb tuaj yeem tsim cov qauv martensitic kom loj tshaj plaws. Thaum qhov txias txias tsawg dua qhov txias tseem ceeb, cov qauv tsis yog martensitic xws li bainite yuav tshwm sim hauv cov qauv crystallization ntawm workpiece. Txawm li cas los xij, qhov txias txias siab dua, qhov zoo dua, qhov txias txias siab dua yuav ua rau tawg ntawm cov khoom tsim, thiab qhov txias txias tsim nyog yuav tsum tau txiav txim siab raws li cov khoom siv sib xyaw thiab cov txheej txheem ntawm cov khoom.

Vim tias qhov tsim ntawm cov yeeb nkab txias muaj feem cuam tshuam ncaj qha rau qhov loj ntawm qhov ceev ntawm qhov txias, cov yeeb nkab txias feem ntau yog tsim los ntawm qhov kev xav ntawm qhov siab tshaj plaws ntawm kev hloov pauv cua sov, yog li qhov kev taw qhia ntawm cov yeeb nkab txias tsim yog qhov nyuaj dua, thiab nws nyuaj rau tau txais los ntawm kev siv tshuab tom qab ua tiav ntawm kev pwm casting. Yuav kom tsis txhob raug txwv los ntawm kev ua haujlwm siv tshuab, txoj kev khaws cov dej ua ntej pwm casting feem ntau raug xaiv.

Vim tias nws ua haujlwm tau ntev ntawm 200 ℃ txog 880 ~ 950 ℃ nyob rau hauv qhov kub thiab txias heev, cov khoom siv pwm kub yuav tsum muaj kev ruaj khov zoo thiab kev ua haujlwm thermal, thiab tuaj yeem tiv taus qhov kev sib txhuam thermal muaj zog los ntawm billet ntawm qhov kub siab thiab qhov cuam tshuam ntawm cov khoom oxide txheej poob. Tsis tas li ntawd, cov khoom pwm yuav tsum muaj kev tiv thaiv corrosion zoo rau cov dej txias kom ntseeg tau tias cov yeeb nkab txias ntws zoo.

Txiav thiab tho qhov

Vim tias lub zog ntawm cov khoom tom qab kub stamping ncav cuag li 1500MPa, yog tias siv cov xovxwm txiav thiab xuas nrig ntaus, qhov xav tau ntawm cov khoom siv loj dua, thiab qhov hnav ntawm ntug txiav tuag yog qhov loj heev. Yog li ntawd, cov chav txiav laser feem ntau siv los txiav cov npoo thiab qhov.

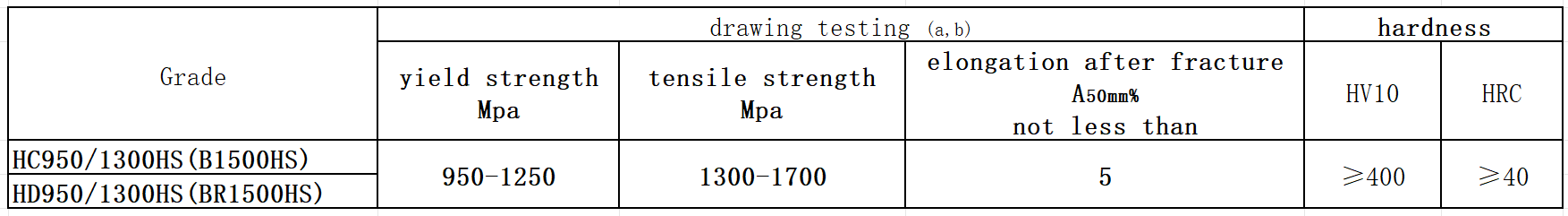

4. Cov qib sib txawv ntawm cov hlau kub stamping

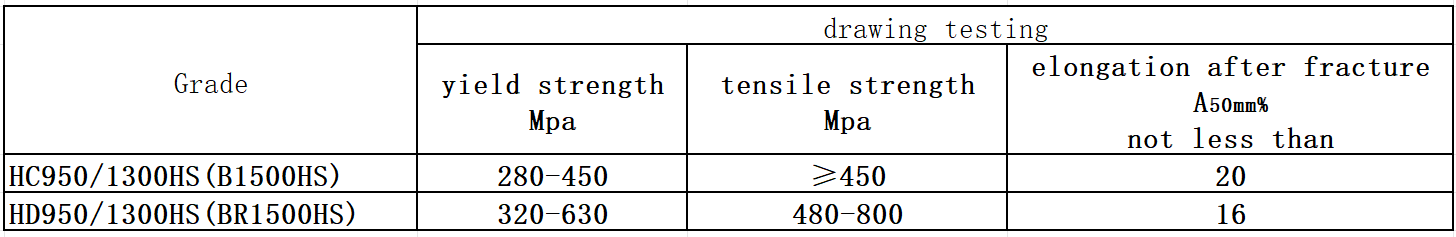

Kev ua tau zoo ua ntej stamping

Kev ua tau zoo tom qab stamping

Tam sim no, qib feem ntau ntawm cov hlau kub stamping yog B1500HS. Lub zog tensile ua ntej stamping feem ntau yog ntawm 480-800MPa, thiab tom qab stamping, lub zog tensile tuaj yeem ncav cuag 1300-1700MPa. Uas yog hais tias, lub zog tensile ntawm 480-800MPa steel phaj, los ntawm kev kub stamping tsim, tuaj yeem tau txais lub zog tensile ntawm kwv yees li 1300-1700MPa qhov chaw.

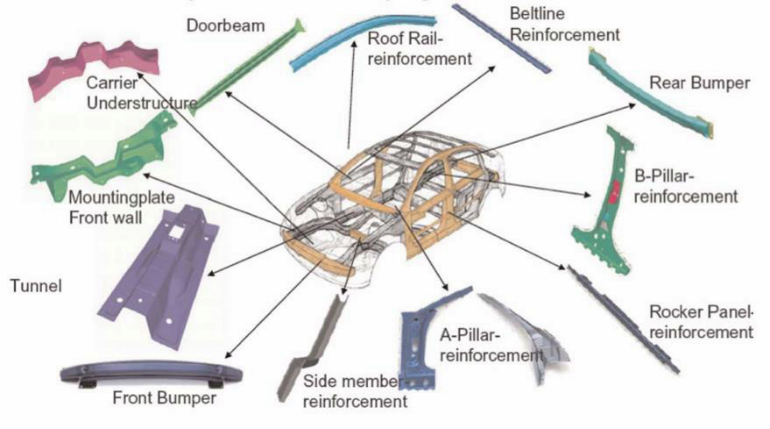

5. Kev siv cov hlau kub stamping

Kev siv cov khoom siv kub stamping tuaj yeem txhim kho kev nyab xeeb ntawm kev sib tsoo ntawm lub tsheb thiab ua kom lub cev tsheb sib dua thiab dawb. Tam sim no, kev siv tshuab kub stamping tau siv rau cov khoom siv dawb ntawm lub cev tsheb, xws li lub tsheb, ncej A, ncej B, lub bumper, lub qhov rooj thiab lub ru tsev thiab lwm yam khoom. Saib daim duab 3 hauv qab no rau piv txwv li cov khoom siv uas haum rau qhov hnyav sib dua.

daim duab 3: Cov khoom siv dawb uas tsim nyog rau kev kub stamping

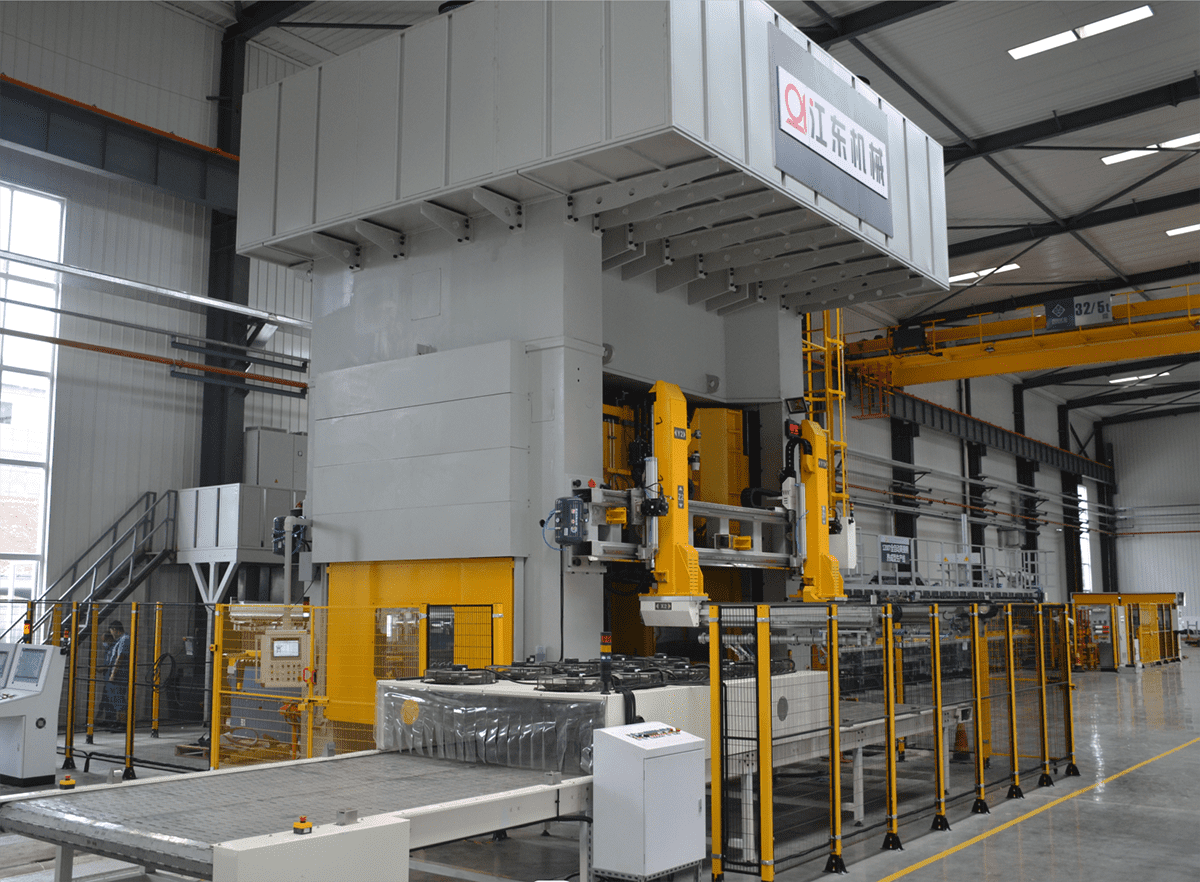

Daim Duab 4: jiangdong machinery 1200 Ton Hot Stamping Press Line

Tam sim no, JIANGDONG MACHINERY kub stamping hydraulic xovxwm ntau lawm kab kev daws teeb meem tau paub tab thiab ruaj khov, hauv Suav teb kub stamping tsim teb yog qib ua tus thawj coj, thiab raws li Tuam Tshoj Tshuab Tool Association forging machinery ceg tus lwm thawj coj chav tsev nrog rau cov tswv cuab ntawm Tuam Tshoj Forging Machinery Standardization Committee, peb kuj tau ua kev tshawb fawb thiab daim ntawv thov ua haujlwm ntawm lub teb chaws super high speed kub stamping ntawm hlau thiab txhuas, uas tau ua lub luag haujlwm loj hauv kev txhawb nqa kev txhim kho ntawm kev lag luam kub stamping hauv Suav teb thiab txawm tias lub ntiaj teb.