-

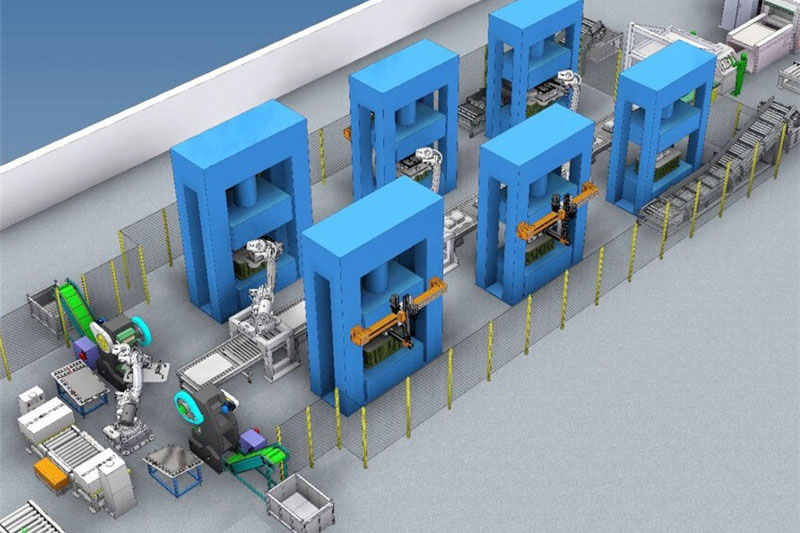

stainless hlau dej dab dej ntau lawm kab

Lub stainless hlau dej dab dej ntau lawm kab yog ib tug automated manufacturing kab uas muaj xws li cov txheej txheem xws li steel coil unwinding, txiav, thiab stamping los tsim cov dab dej. Cov kab ntau lawm no siv cov neeg hlau los hloov cov neeg ua haujlwm hauv phau ntawv, tso cai rau kev ua tiav ntawm lub dab ntxuav muag.

Stainless hlau dej dab dej ntau lawm kab muaj ob qhov tseem ceeb: cov khoom siv thiab lub dab dej stamping unit. Ob qhov no yog txuas nrog lub logistics hloov chaw, uas pab txhawb kev thauj mus los ntawm cov khoom nruab nrab ntawm lawv. Cov khoom siv hauv tsev muaj xws li cov khoom siv xws li coil unwinders, film laminators, flatteners, cutters, thiab stackers. Lub logistics hloov chaw muaj xws li cov tsheb thauj mus los, cov khoom siv stacking kab, thiab khoob pallet cia kab. Lub tshuab stamping muaj plaub txheej txheem: lub kaum sab xis txiav, thawj stretching, theem nrab stretching, ntug trimming, uas koom nrog kev siv hydraulic presses thiab neeg hlau automation.

Lub peev xwm ntau lawm ntawm cov kab no yog 2 daim ib feeb, nrog rau txhua xyoo tso zis ntawm kwv yees li 230,000 daim.

-

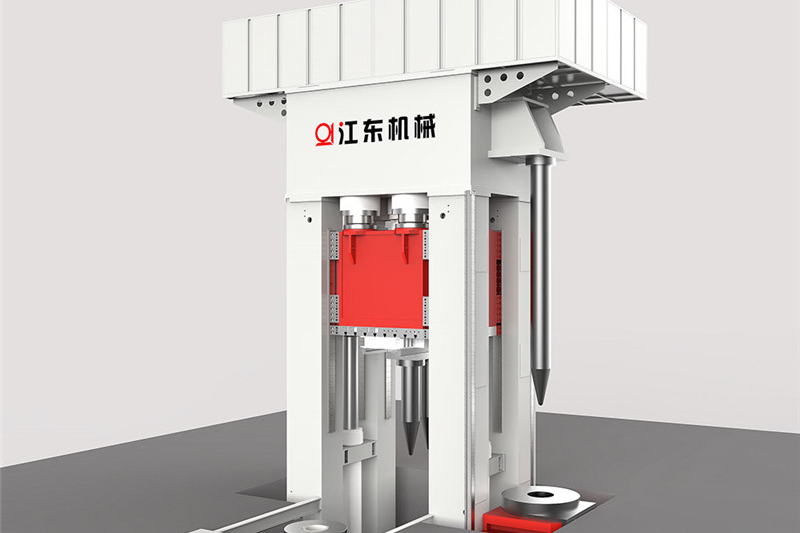

SMC/BMC/GMT/PCM Composite Moulding Hydraulic Xovxwm

Yuav kom tswj tau meej thaum lub sij hawm molding txheej txheem, hydraulic xovxwm yog nruab nrog ib tug advanced servo hydraulic tswj system. Lub kaw lus no txhim kho txoj haujlwm tswj, tswj ceev, tswj micro qhib ceev, thiab qhov ntsuas qhov tseeb. Lub siab tswj qhov tseeb tuaj yeem ncav cuag ± 0.1MPa. Tsis muaj xws li swb txoj hauj lwm, downward ceev, pre-nias ceev, micro qhib ceev, rov qab ceev, thiab tso zis zaus yuav tsum tau teem thiab kho nyob rau hauv ib tug tej yam ntau yam ntawm kov screen. Cov kev tswj hwm yog lub zog-txuag, nrog lub suab qis thiab qhov cuam tshuam hydraulic tsawg, muab kev ruaj ntseg siab.

Txhawm rau daws cov teeb meem kev lag luam xws li cov khoom tsis sib xws los ntawm asymmetric molded qhov chaw thiab thickness sib txawv hauv cov khoom loj tiaj tiaj, lossis kom ua tau raws li cov txheej txheem xws li txheej txheej pwm thiab sib npaug demolding, hydraulic xovxwm tuaj yeem nruab nrog lub tshuab hluav taws xob dynamic instantaneous plaub-kab leveling ntaus ntawv. Cov cuab yeej no siv cov cuab yeej hloov pauv siab thiab cov lus teb ntau zaus servo li qub los tswj cov kev hloov kho synchronous ntawm plaub lub tog raj kheej actuators. Nws ua tiav qhov siab tshaj plaws plaub-kab theem qhov tseeb txog li 0.05mm ntawm tag nrho cov lus.

-

LFT-D ntev fiber reinforced thermoplastic compression ncaj molding ntau lawm kab

LFT-D ntev fiber reinforced thermoplastic compression ncaj qha molding cov kab ntau lawm yog cov kev daws teeb meem zoo rau kev tsim cov khoom zoo sib xws. Cov kab ntau lawm no muaj cov iav fiber ntau yarn guiding system, ib tug ntxaib-ntsia hlau iav fiber ntau yas mixing extruder, thaiv cua sov conveyor, ib tug neeg hlau khoom tuav system, ceev hydraulic xovxwm, thiab ib tug centralized tswj chav tsev.

Cov txheej txheem ntau lawm pib nrog nruam iav fiber ntau pub rau hauv extruder, qhov twg nws raug txiav thiab extruded rau hauv daim ntawv pellet. Tom qab ntawd cov pellets yog rhuab thiab molded sai sai rau hauv cov duab uas xav tau siv cov khoom siv neeg hlau tuav thiab cov xovxwm ceev hydraulic. Nrog rau txhua xyoo muaj peev xwm tsim tau ntawm 300,000 txog 400,000 strokes, cov kab ntau lawm no ua kom muaj txiaj ntsig zoo.

-

Carbon Fiber High Pressure Resin Transfer Moulding (HP-RTM) cov khoom siv

Cov khoom siv Carbon Fiber High Pressure Resin Transfer Molding (HP-RTM) yog ib qho kev daws teeb meem uas tsim hauv tsev rau kev tsim cov khoom zoo carbon fiber ntau. Cov kab ntau lawm no suav nrog cov txheej txheem kev xaiv ua ntej, HP-RTM tshwj xeeb xovxwm, HP-RTM siab-siab resin txhaj system, neeg hlau, chaw tswj kab ntau lawm, thiab qhov chaw xaiv machining. Lub HP-RTM high-pressure resin txhaj tshuaj muaj lub ntsuas ntsuas, lub tshuab nqus tsev, qhov ntsuas kub, thiab cov khoom siv thauj mus los thiab khaws cia. Nws siv lub siab-siab, reactive txhaj tshuaj nrog peb cov khoom siv. Cov xovxwm tshwj xeeb yog nruab nrog plaub-txheej txheej txheej txheem, muab qhov ntsuas qhov tseeb ntawm 0.05mm. Nws kuj tseem muaj peev xwm qhib micro-qhib, tso cai rau kev ua haujlwm sai ntawm 3-5 feeb. Cov cuab yeej no ua rau cov khoom tsim tawm thiab kho kom haum rau kev ua haujlwm ntawm cov khoom siv fiber ntau.

-

Hlau extrusion / kub tuag forging hydraulic xovxwm

Hlau extrusion / kub tuag forging hydraulic xovxwm yog ib qho kev tsim technology siab heev rau kev ua tau zoo, muaj txiaj ntsig, thiab kev siv qis ntawm cov khoom siv hlau nrog tsawg lossis tsis muaj cov chips txiav. Nws tau txais kev siv dav hauv ntau yam kev lag luam xws li tsheb, tshuab, kev lag luam teeb, aerospace, tiv thaiv, thiab khoom siv hluav taws xob.

Hlau extrusion / kub tuag forging hydraulic xovxwm tshwj xeeb yog tsim los rau txias extrusion, sov extrusion, sov forging, thiab kub tuag forging txheej txheem, raws li zoo raws li precision tiav ntawm hlau Cheebtsam.

-

titanium alloy superplastic sib sau hydraulic xovxwm

Lub Superplastic Forming Hydraulic xovxwm yog lub tshuab tshwj xeeb tsim los rau ze-net txoj kev ntawm cov khoom sib txuas ua los ntawm cov ntaub ntawv nyuaj nrog qhov nqaim deformation kub thiab siab deformation kuj. Nws pom cov ntawv thov dav dav hauv kev lag luam xws li aerospace, aviation, tub rog, tiv thaiv, thiab kev tsheb ciav hlau ceev.

Cov xovxwm hydraulic no siv cov khoom siv superplasticity, xws li titanium alloys, aluminium alloys, magnesium alloys, thiab high-temperature alloys, los ntawm kev kho cov nplej loj ntawm cov khoom siv raw rau lub xeev superplastic. Los ntawm kev siv ultra-siab siab thiab tswj ceev, cov xovxwm ua tiav superplastic deformation ntawm cov khoom. Cov txheej txheem kev tsim khoom hloov pauv no ua rau cov khoom tsim khoom siv cov khoom me me piv rau cov txheej txheem sib sau ua ke.

-

Free forging hydraulic xovxwm

Lub Free Forging Hydraulic Xovxwm yog lub tshuab tshwj xeeb tsim los rau kev ua haujlwm loj-dawb forging. Nws ua kom tiav cov txheej txheem forging ntau yam xws li elongation, chim siab, xuas nrig ntaus, nthuav dav, kos duab kos, twisting, khoov, hloov, thiab chopping rau kev tsim cov shafts, rods, daim hlau, discs, rings, thiab cov khoom tsim los ntawm cov voj voog thiab square duab. Nruab nrog cov khoom siv sib txuas ntxiv xws li forging machinery, cov khoom siv tuav, cov khoom siv teb, lub tog raj kheej, thiab cov tshuab nqa, cov xovxwm seamlessly integrates nrog cov khoom no kom tiav cov txheej txheem forging. Nws pom kev siv dav hauv kev lag luam xws li aerospace thiab aviation, nkoj tsim, tsim hluav taws xob, hluav taws xob nuclear, metallurgy, thiab petrochemicals.

-

Lub teeb Alloy Liquid Tuag Forging/semisolid forming Ntau lawm kab

Lub Teeb Alloy Liquid Die Forging Ntau Lawm Kab yog lub xeev-ntawm-tus-kos duab thev naus laus zis uas muab cov txiaj ntsig zoo ntawm casting thiab forging txheej txheem kom ua tiav qhov ze-net zoo sib sau. Cov kab tsim tawm tshiab no muaj ntau yam txiaj ntsig, suav nrog cov txheej txheem luv luv, kev ua phooj ywg ib puag ncig, kev siv hluav taws xob tsawg, cov qauv sib xws, thiab kev ua haujlwm siab. Nws muaj ntau hom CNC kua tuag forging hydraulic xovxwm, ib qho txhuas ua kua kom muaj nuj nqis pouring system, ib tug neeg hlau, thiab ib lub tsheb npav integrated system. Cov kab ntau lawm yog tus cwj pwm los ntawm nws cov CNC tswj, ntse nta, thiab yooj.

-

Vertical Gas Cylinder / Bullet Housing Drawing Kab Ntau Lawm

Vertical Gas Cylinder / Bullet Housing Drawing Kab Ntau Lawm yog tsim tshwj xeeb rau kev tsim cov khob-zoo li lub tog raj kheej (chim-puab) nrog cov tuab hauv qab kawg, xws li ntau lub thawv, roj cylinders, thiab cov mos txwv vaj tse. Cov kab ntau lawm no ua rau peb txoj haujlwm tseem ceeb: chim siab, xuas nrig ntaus, thiab kos duab. Nws suav nrog cov khoom siv xws li lub tshuab pub mis, nruab nrab zaus cua sov rauv, conveyor siv, pub neeg hlau / tshuab tes, chim siab thiab xuas nrig ntaus hydraulic xovxwm, dual-chaw nres tsheb swb rooj, hloov neeg hlau / tshuab tes, kos duab hydraulic xovxwm, thiab cov khoom siv hloov khoom siv.

-

Gas Lub tog raj kheej Kab rov tav kos duab ntau lawm kab

Cov roj thooj voos kheej kheej kab rov tav kab kos duab ntau lawm yog tsim los rau cov txheej txheem ncab ntawm cov roj kheej kheej ntev ntev. Nws siv cov txheej txheem kab rov tav stretching txoj kev, muaj xws li kab taub hau chav tsev, khoom thauj neeg hlau, ntev-stroke kab rov tav xovxwm, khoom-retreating mechanism, thiab kab tail unit. Cov kab ntau lawm no muaj ntau yam zoo xws li kev ua haujlwm yooj yim, kev sib sau ua haujlwm siab, ntev stretching stroke, thiab qib siab ntawm automation.

-

Gantry Straightening Hydraulic Xovxwm rau daim hlau

Peb gantry straightening hydraulic xovxwm yog tsim tshwj xeeb rau kev ncaj thiab tsim cov txheej txheem ntawm cov hlau phaj hauv kev lag luam xws li aerospace, shipbuilding, thiab metallurgy. Cov khoom siv muaj lub taub hau lub tog raj kheej txav tau, lub gantry ncej txawb, thiab lub rooj ua haujlwm ruaj khov. Nrog lub peev xwm los ua txoj kab rov tav txav ntawm ob lub tog raj kheej lub taub hau thiab lub gantry ncej raws li qhov ntev ntawm lub rooj ua haujlwm, peb cov gantry straightening hydraulic xovxwm xyuas kom meej thiab meej kho phaj yam tsis muaj qhov muag tsis pom kev. Lub tog raj kheej tseem ceeb ntawm cov xovxwm yog nruab nrog lub micro txav downward muaj nuj nqi, tso cai rau cov phaj ncaj ncaj. Tsis tas li ntawd, lub rooj ua haujlwm yog tsim los nrog ntau lub lifting thooj voos kheej kheej hauv thaj chaw phaj zoo, uas ua kom yooj yim rau kev nkag mus ntawm kev kho cov blocks ntawm cov ntsiab lus tshwj xeeb thiab tseem pab txhawb nqa cov phaj.ifting ntawm lub phaj.

-

Tsis Siv Neeg Gantry Straightening Hydraulic Xovxwm rau Bar Tshuag

Peb tsis siv neeg gantry straightening hydraulic xovxwm yog ua tiav cov kab ntau lawm tsim kom muaj txiaj ntsig ncaj thiab raug hlau bar Tshuag. Nws muaj xws li mobile hydraulic straightening unit, nrhiav kom tau qhov system (xws li workpiece straightness nrhiav kom tau, workpiece angle rotation detection, straightening point deb nrhiav kom tau, thiab straightening displacement nrhiav kom tau), hydraulic tswj system, thiab hluav taws xob tswj system. Qhov no ntau yam hydraulic xovxwm muaj peev xwm ntawm automating lub straightening txheej txheem rau hlau bar Tshuag, kom ntseeg tau superior raug thiab efficiency.